CFR-25JB-52-1M1 Mica and PTFE Capacitors highlighting the core functional technology articles and application development cases of Mica and PTFE Capacitors that are effective.

System

May 29

0

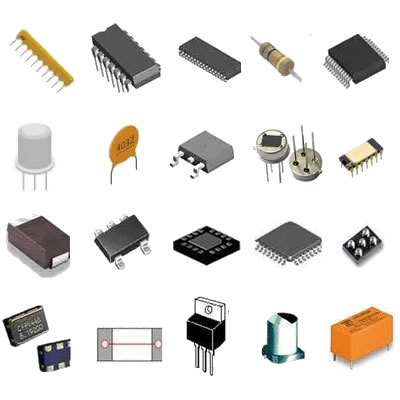

Mica and PTFE Capacitors: Core Functional Technologies and Application Development CasesMica and PTFE (Polytetrafluoroethylene) capacitors are specialized electronic components known for their unique properties, making them indispensable in various high-performance applications. Below, we delve into the core functional technologies and notable application development cases for these capacitors.

Core Functional Technologies 1. Mica Capacitors

- **Dielectric Properties**: Mica capacitors utilize natural mica as a dielectric material, which provides exceptional thermal stability, low loss, and high insulation resistance. This makes them particularly suitable for high-frequency applications.

- **Temperature Stability**: These capacitors exhibit minimal capacitance variation across a wide temperature range, making them ideal for precision applications where stability is critical.

- **High Voltage Ratings**: Mica capacitors can handle high voltage applications, often exceeding 1 kV, which is advantageous in power electronics and RF applications.

- **Low ESR and ESL**: With low equivalent series resistance (ESR) and equivalent series inductance (ESL), mica capacitors enhance performance in high-frequency circuits, reducing signal distortion and improving efficiency. 2. PTFE Capacitors

- **Chemical Resistance**: PTFE capacitors are highly resistant to chemicals and moisture, making them suitable for harsh environments, including industrial and outdoor applications.

- **High Dielectric Strength**: PTFE's high dielectric strength allows for the design of capacitors that can operate at elevated voltages, enhancing their applicability in demanding environments.

- **Low Loss Factor**: These capacitors exhibit low dielectric losses, making them ideal for RF and microwave applications where signal integrity is paramount.

- **Wide Temperature Range**: PTFE capacitors can operate effectively over a broad temperature range, typically from -55°C to +200°C, ensuring reliability in extreme conditions. Application Development Cases 1. Aerospace and Defense

- **Use Case**: Mica capacitors are integral in aerospace applications, including radar systems, communication devices, and navigation systems. Their reliability and stability under extreme conditions are critical for mission success.

- **Example**: In military avionics, mica capacitors are used in high-frequency oscillators and filters, ensuring precise signal processing. 2. Telecommunications

- **Use Case**: PTFE capacitors are prevalent in telecommunications equipment, such as base stations and satellite communications, due to their low loss characteristics and ability to handle high frequencies.

- **Example**: In 5G infrastructure, PTFE capacitors are employed in RF amplifiers and filters, enabling efficient signal transmission and reception. 3. Medical Devices

- **Use Case**: Both mica and PTFE capacitors are utilized in medical devices, including imaging equipment and diagnostic tools, where precision and reliability are paramount.

- **Example**: Mica capacitors are found in MRI machines, where their stability at high frequencies is essential for accurate imaging. 4. Industrial Equipment

- **Use Case**: Mica capacitors are used in industrial applications, such as motor drives and power supplies, where high voltage and temperature stability are required. PTFE capacitors are also employed in industrial sensors and control systems due to their chemical resistance.

- **Example**: In automated manufacturing systems, mica capacitors are used in power inverters to ensure efficient energy conversion. 5. Consumer Electronics

- **Use Case**: In high-end audio equipment, mica capacitors are favored for their low distortion and high fidelity. PTFE capacitors are also utilized in high-performance audio applications, where signal integrity is crucial.

- **Example**: Audiophile-grade amplifiers often incorporate mica capacitors in their signal paths to maintain audio clarity and detail. 6. Automotive Applications

- **Use Case**: With the rise of electric vehicles, both mica and PTFE capacitors are increasingly used in power electronics, battery management systems, and electric drive systems due to their ability to handle high voltages and temperatures.

- **Example**: In electric vehicle powertrains, PTFE capacitors are used in DC-DC converters to ensure efficient power management and thermal stability. ConclusionMica and PTFE capacitors are essential components in various high-performance applications due to their unique properties. Their reliability, stability, and performance in extreme conditions make them suitable for critical applications in aerospace, telecommunications, medical devices, and more. As technology continues to advance, the demand for these capacitors is likely to grow, leading to further innovations and applications in the field. The ongoing development of new materials and manufacturing techniques will likely enhance the capabilities and applications of mica and PTFE capacitors, solidifying their role in the future of electronics.

Read more