The latest fixed inductor specifications

The Latest Fixed Inductor Specifications

I. Introduction

A. Definition of Fixed Inductors

Fixed inductors are passive electronic components that store energy in a magnetic field when electrical current flows through them. Unlike variable inductors, which allow for adjustments in inductance, fixed inductors have a predetermined inductance value, making them essential in various electronic applications.

B. Importance of Inductors in Electronic Circuits

Inductors play a crucial role in electronic circuits, serving functions such as energy storage, filtering, and signal processing. They are integral to power supplies, radio frequency (RF) applications, and many other electronic systems. Understanding the specifications of fixed inductors is vital for engineers and designers to ensure optimal performance in their applications.

C. Purpose of the Article

This article aims to provide an overview of the latest specifications and trends in fixed inductors, helping readers understand their importance and how to select the right inductor for their needs.

II. Overview of Fixed Inductors

1. Basic Principles of Inductance

Inductance is the property of an electrical conductor that opposes changes in current. When current flows through a coil of wire, it generates a magnetic field around it. If the current changes, the magnetic field also changes, inducing a voltage that opposes the change in current. This phenomenon is known as self-induction.

2. Components and Construction

Fixed inductors typically consist of a coil of wire wound around a core material, which can be air, iron, or ferrite. The core material influences the inductor's performance characteristics, such as inductance value, saturation current, and efficiency.

1. Air-Core Inductors

Air-core inductors use air as the core material. They are lightweight and have low losses, making them suitable for high-frequency applications. However, they typically have lower inductance values compared to other types.

2. Iron-Core Inductors

Iron-core inductors use iron as the core material, which increases the inductance value due to the higher magnetic permeability of iron. They are commonly used in power applications but can suffer from core losses at high frequencies.

3. Ferrite-Core Inductors

Ferrite-core inductors use ferrite materials, which are ceramic compounds that exhibit magnetic properties. They are popular in RF applications due to their high inductance values and low core losses at high frequencies.

1. Power Supplies

Fixed inductors are widely used in power supply circuits to filter out noise and smooth voltage levels. They help maintain stable output by storing energy and releasing it as needed.

2. RF Applications

In RF circuits, fixed inductors are used in tuning circuits, oscillators, and filters. Their ability to handle high frequencies makes them essential for communication devices.

3. Signal Processing

Inductors are used in various signal processing applications, including audio equipment and signal conditioning circuits, where they help filter and shape signals.

III. Key Specifications of Fixed Inductors

1. Measurement Units

Inductance is measured in Henries (H), with common subunits being millihenries (mH) and microhenries (µH). The inductance value determines how much energy the inductor can store.

2. Tolerance Levels

Tolerance indicates the allowable variation in inductance value. Common tolerance levels range from ±5% to ±20%, depending on the application requirements.

1. Saturation Current

Saturation current is the maximum current an inductor can handle before its inductance value begins to decrease significantly. Exceeding this current can lead to overheating and damage.

2. RMS Current

RMS (Root Mean Square) current is the effective current that the inductor can handle continuously without overheating. It is crucial to consider both saturation and RMS current ratings when selecting an inductor.

1. Importance of DCR in Performance

DC resistance affects the efficiency of the inductor. Higher DCR leads to greater power losses in the form of heat, which can impact overall circuit performance.

2. Measurement Techniques

DCR is typically measured using a precision ohmmeter or an LCR meter, which can provide accurate readings of the inductor's resistance.

1. Definition and Significance

The quality factor (Q) is a measure of an inductor's efficiency, defined as the ratio of its inductive reactance to its resistance at a specific frequency. A higher Q indicates lower energy losses and better performance.

2. Factors Affecting Q

Several factors can influence the Q factor, including the core material, winding technique, and frequency of operation. Designers should consider these factors when selecting inductors for high-performance applications.

1. Explanation of SRF

The self-resonant frequency is the frequency at which the inductor's reactance becomes zero due to the effects of parasitic capacitance. Beyond this frequency, the inductor behaves more like a capacitor.

2. Implications for Circuit Design

Understanding the SRF is crucial for circuit designers, as operating an inductor above its SRF can lead to unintended behavior and reduced performance.

IV. Recent Trends in Fixed Inductor Technology

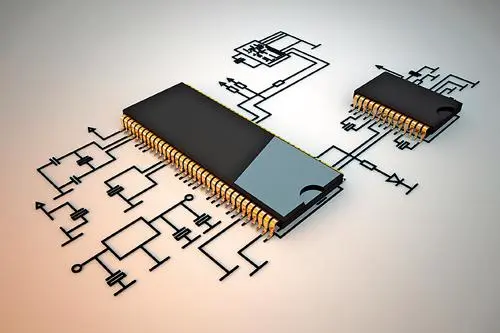

1. Impact on Performance and Applications

The trend towards miniaturization has led to the development of smaller, high-density inductors that can fit into compact electronic devices. These inductors maintain performance while reducing size, making them ideal for modern applications.

2. Examples of Compact Designs

Manufacturers are now producing inductors with integrated designs that combine multiple functions, such as filtering and energy storage, into a single component.

1. Use of Advanced Core Materials

Innovations in core materials, such as nanocrystalline and amorphous alloys, have improved the performance of fixed inductors, allowing for higher efficiency and lower losses.

2. Innovations in Winding Techniques

New winding techniques, such as multilayer and planar designs, have enhanced the performance of inductors by reducing parasitic effects and improving thermal management.

1. RoHS Compliance and Lead-Free Options

With increasing regulations on hazardous materials, many manufacturers are producing RoHS-compliant inductors that are lead-free and environmentally friendly.

2. Sustainable Manufacturing Practices

Sustainability is becoming a priority in the manufacturing process, with companies adopting practices that reduce waste and energy consumption.

V. Selecting the Right Fixed Inductor

1. Application Requirements

When selecting a fixed inductor, it is essential to consider the specific requirements of the application, including inductance value, current ratings, and operating frequency.

2. Performance Specifications

Evaluating performance specifications such as DCR, Q factor, and SRF will help ensure that the chosen inductor meets the necessary criteria for optimal performance.

1. Overlooking Thermal Management

One common mistake is neglecting thermal management, which can lead to overheating and reduced reliability. Proper heat dissipation techniques should be considered in the design.

2. Ignoring the Impact of Parasitics

Designers often overlook the effects of parasitic capacitance and resistance, which can significantly impact the performance of inductors in high-frequency applications.

VI. Future Directions in Fixed Inductor Development

1. Integration with Other Components

Future developments may see fixed inductors integrated with other components, such as capacitors and resistors, to create multifunctional devices that enhance circuit performance.

2. Smart Inductors with Built-in Sensors

The rise of smart technology may lead to the development of inductors with built-in sensors that can monitor performance and provide real-time data for improved circuit management.

1. Growth in Specific Industries

The demand for fixed inductors is expected to grow in industries such as automotive, telecommunications, and renewable energy, driven by the increasing need for efficient power management solutions.

2. Potential Challenges and Opportunities

While the market presents numerous opportunities, challenges such as supply chain disruptions and the need for continuous innovation will require manufacturers to adapt and evolve.

VII. Conclusion

A. Recap of Key Points

Fixed inductors are essential components in electronic circuits, with specifications such as inductance value, current rating, DCR, Q factor, and SRF playing critical roles in their performance. Understanding these specifications is vital for selecting the right inductor for specific applications.

B. The Importance of Staying Updated with Specifications

As technology advances, staying informed about the latest specifications and trends in fixed inductors is crucial for engineers and designers to ensure optimal performance in their projects.

C. Encouragement for Further Research and Development in Inductor Technology

The field of inductor technology is continuously evolving, and further research and development will lead to innovative solutions that meet the demands of modern electronics. Embracing these advancements will pave the way for more efficient and effective electronic designs.

VIII. References

- Academic Journals

- Industry Reports

- Manufacturer Specifications and Data Sheets

This comprehensive overview of fixed inductors highlights their significance in electronic circuits and the latest trends in specifications and technology. By understanding these components, engineers can make informed decisions that enhance the performance and reliability of their designs.